Micro Tracers Services Europe

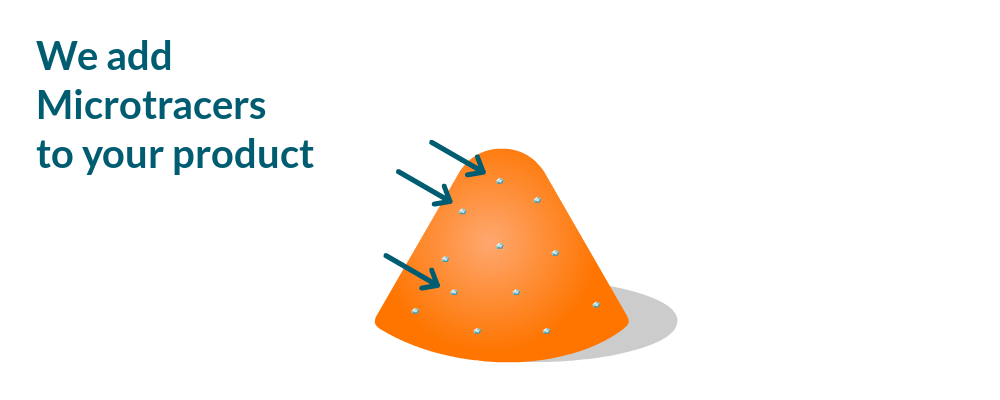

MTSE GmbH offers a complete service for your customers. Services involving everything related to the optimisation of mixing processes range from correct sampling methods to the validation of mixing quality and the determination of the carry-over level, right through to training seminars on the Microtracer analytical method.

Along with these services, MTSE also provides you with the necessary equipment.

Ask us.

Micro Tracers Services Europe GmbH is a joint venture of Micro-Tracers Inc., Jadis-Additiva B. V. and Dr. Sabine Artelt as managing partner.

MTSE GmbH was established in 2000.

Meet us on

EuroTier 2022

November 15th to 18th 2022

Here’s what our customers say

Testimonials

-

Norbert Vaje (Technischer Leiter)

Norbert Vaje (Technischer Leiter)

Rondo Food GmbH & Co. KG (Snackprodukte)

Krefeld, Deutschland

www.rondofood.de“The stability of the Microtracers was the decisive argument for us. Our extruded snack foods for dogs and cats are manufactured under extreme conditions. This method has enabled us to clearly prove the high quality of our product.”

-

Nils Lastein (Application Manager, Feed)

Nils Lastein (Application Manager, Feed)

Andritz Feed & Biofuel A/S (Mixer Producer)

Esbjerg, Denmark

www.andritz.com"Microtracer are our choice for testing new mixers. The different Microtracer colours allow us to check the homogeneity in our mixer for different mixing times in one batch only."

-

Dr. Sönke Landgraf (Geschäftsführender Gesellschafter)

Dr. Sönke Landgraf (Geschäftsführender Gesellschafter)

Lexa Tierernährung (Mineralfutterhersteller)

Kirchheim/Allgäu, Deutschland

www.lexa-pferdefutter.de“No products for one species may be allowed to carry over into the next production batch for another species at any time. We have determined the level of carry-over on-site with Microtracers.”

-

Hans Van Gorp (Managing Director)

Hans Van Gorp (Managing Director)

Van Gorp Diervoeders B.V. (Organic Feed)

Waalwijk, Netherlands

www.van-gorp.com"We are testing our production lines in both of our factories. Microtracer is used as well in regular as in organic certified feed, because they are not toxic or doing any harm to the environment."

-

Karl Schulze König (Geschäftsführer)

Karl Schulze König (Geschäftsführer)

SKS Schulze König Zucht- und Nutztiere GmbH & Co. KG

Steinfurt-Borghorst, Deutschland

www.sks-sau.de“As a state-approved breeding operation, the health of our animals is of prime importance to us. For our feed, we use only the highest quality components. Microtracers have enabled us to rapidly determine the correct mixing time for our special feeds.”

-

Mr. Marnix de Schrijver (Head of Lab)

Mr. Marnix de Schrijver (Head of Lab)

FFQ Laboratorium

Merksem, Belgium

www.ffq.be"Microtracer Analysis of homogeneity and cross-contamination is a service to our customers. Contamination sources in a production line can be detected easily."

Contact & Team

-

Micro Tracers Services Europe GmbH

Zur Kalkbahn 30

D-52379 LangerweheFon: +49-2423-40780-97

info@microtracer.de

Fax: +49-2423-40780-98 -

Dr. Sabine Artelt

Chemist

Managing director

s.artelt@microtracer.de -

Claudia Langerscheidt

Laboratory

Quality management

c.langerscheidt@microtracer.de -

Kirsten Schmitz

Laboratory

k.schmitz@microtracer.de

Publications

-

"Feed Magazine | Kraftfutter" Nr. 7-8/2020

Determining the mixing precision

PDF -

Article in "Mühle & Mischfutter" Issue 21, 08.11.2018

Simultaneous Carry-Over Analysis of Various Locations

before the Mixer with Microtracer.

PDF -

"PETS International" October 2018

Frequent analysis of homogeneity and carry-over is needed to guarantee product safety and excellence for consumers in the pet food industry.

PDF -

Trade journal “Feed Magazine | Kraftfutter” no. 3/2009

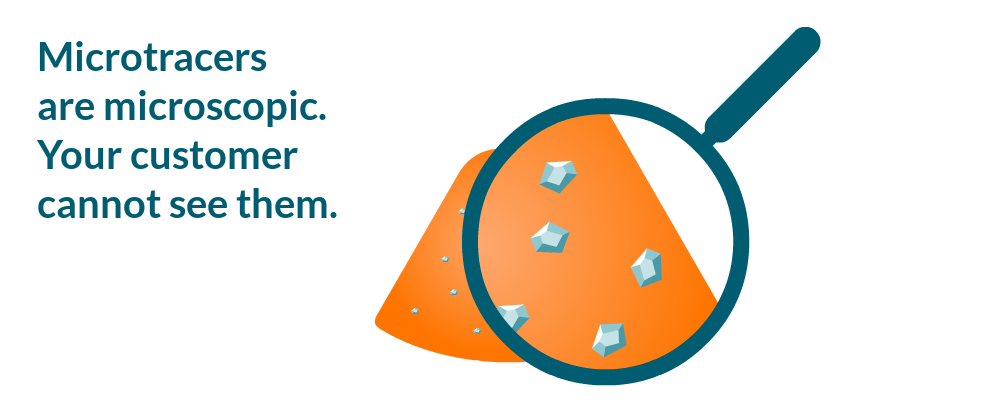

The Microtracer analytical method is a reliable method for determining homogeneity and cross-over in mixing equipment in accordance with Feed Hygiene Regulation (EC) no. 183/2005.

PDF -

Trade journal “De Molenaar” no. 11/2014

Microtracers are not classified as dangerous according to REACH Regulation (EC) no. 1907/2006 and are increasingly used as a preventive measure for the traceability of feedstuffs in order to guarantee safe products.

PDF -

Trade journal “De Molenaar” no. 21/2006

The “direct” Microtracer method relies on the particle count principle and not on the measurement of concentrations. As a result, influences on mixing processes such as the tapping of filters are recognised with significantly greater precision and clarity.

PDF

Accreditation as laboratory

-

MTSE GmbH is accreditated at the „Deutsche Akkreditierungsstelle GmbH (see code D-PL-21632-01-00)“.

This meets „GMP+FC scheme 2020, BA 2 „Control of residues“, Version 01.04.2019, Chapter 5.7.

Certificate PDF

Attachment of Certificate PDF

Certification of the analytical method

-

GMP+FC scheme 2020

www.gmpplus.org

BA 2: Control of residues, Version EN 1 April 2019, Chapter 5.7

„Checking procedure for the process accuracy of compound feed with micro tracers“

PDF -

GMP+FSA & GMP+FRA

www.gmpplus.org

Support S 9.14 Support Document, Version EN 1 March 2021

„Examples of methods for measuring carry-over and homogeneity“

PDF -

Ovocom

II.2. Methods

General procedure for testing the cross-contamination in the compound feed production by means of a tracer

The procedure for determining the cross-contamination and the homogeneity of flour blends when preparing compound feeds, using tracers which, depending on their properties, can replace the conventional compound feed additives.

PDF

Product specification

Licensed laboratories

MTSE GmbH is working together with licensed laboratories which are regularly taking part in Microtracer proficiency tests.

-

ALPEX FEED D.O.O.

ALPEX FEED D.O.O.

Silbaš, Serbia

www.alpexfeed.rs -

Masterlab (Nutreco Group)

Masterlab (Nutreco Group)

Boxmeer, Netherlands

www.masterlab.nl -

FFQ Laboratorium Feed & Food Quality

FFQ Laboratorium Feed & Food Quality

Antwerpen, Belgium

www.ffq.be -

Nutrilab B.V.

Nutrilab B.V.

Giessen, Netherlands

www.nutrilab.nl -

Veravis

Veravis

Münster, Germany

www.veravis.de -

NutriControl

NutriControl

Veghel, Netherlands

www.nutricontrol.nl -

Mixtura Avanzada

Mixtura Avanzada

Burgos, Spain

www.mixturavanzada.com -

Micro-Tracers Inc.

Micro-Tracers Inc.

San Francisco, CA USA

www.microtracers.com -

Passion4Food

Passion4Food

Ålgård, Norway

www.passion4food.no

In the proficiency testing area, MTSE GmbH works together with Dr. Gerhard Wichmann who is an expert for conducting and evaluating proficiency tests.

-

Dr. Gerhard Wichmann

Dr. Gerhard Wichmann

Buchenstraße 1

D-25486 Alveslohe